As pharmaceutical demand grows, companies need batch production solutions that deliver precision, speed, and cost-efficiency. Injection molding machines, especially in a CDMO or contract-manufacturing setting, offer a scalable route for producing consistent primary packaging, delivery devices, and sterile components.

How Injection Molding Supports Pharma Scalability?

Injection molding uses molten medical‑grade plastics injected into high‑precision molds to produce components like vials, closures, auto‑injector parts, and blister tray inserts.

This automated process ensures:

- High repeatability and tight tolerance across millions of units

- Cost optimization through minimal waste and rapid cycle times

- Complex geometry support, enabling drug delivery innovations like multi-piece injectors or nested components

For contract manufacturers, this capacity is crucial for offering pharma contract manufacturing solutions with integrated device production and scalable fills.

Industry Applications: Why It Matters for Injectables & Devices

Various formulations and therapeutic formats depend on customized plastic components:

- Prefilled syringes and auto‑injectors (requires ergonomic molds)

- Ampoule caps, vial seals, and secondary closures

- Device components such as plungers, dosing rings, and safety guards

- Custom packaging trays and filter holders for sterile processing

High-volume injection molding under controlled conditions maintains product safety, minimizes particulate risk, and supports regulatory compliance in pharma environments.

Benefits for CDMO Partners and OEMs:

1. Operational Efficiency

Automated molding lines reduce cycle times from minutes to seconds, enabling large-scale runs with minimal labor and variation.

2. Reduced Capital Burden

Pharma brands can avoid heavy capital investment in injection molding infrastructure by partnering with contract manufacturers equipped with well‑calibrated machines.

3. Regulatory Alignment

Medical-grade materials and clean-room mold change systems ensure compliance with quality assurance in pharmaceuticals and traceability standards.

4. Design Consistency

Mold-based production guarantees uniformity across millions of units—ideal for pharma brands targeting large, regulated markets.

5. Customization at Scale

Custom mold design lets manufacturers tailor every component to dose delivery, sterility, ergonomics, or shelf display needs.

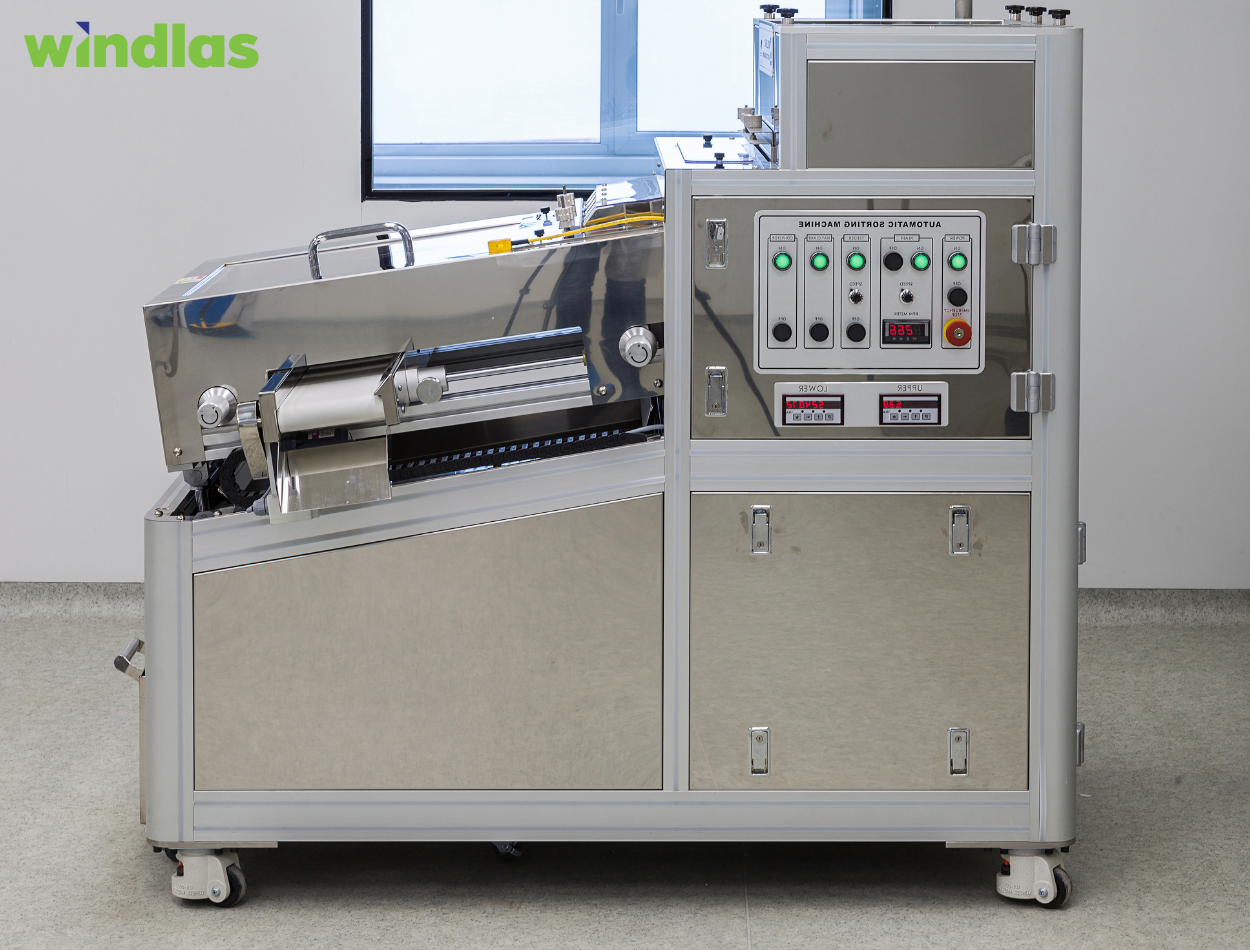

Windlas Biotech’s Injection Molding Capabilities:

Windlas Biotech has strategically expanded its contract manufacturing services in India by integrating injection molding into its injectable and device ecosystem.

Key strengths include:

- ISO-validated mold maintenance systems for batch changeover

- High-throughput molding capacity supporting multiple SKUs simultaneously

- Sterile area molding capabilities for primary packaging materials

- Cross-functional design support, from concept to mold prototyping and validation

- Integration with formulation development and fill‑finish services

This infrastructure supports pharmaceutical partners seeking fully integrated, high-volume manufacturing with enhanced stability and regulatory confidence.

Emerging Trends & Tech in Pharma Injection Molding:

1. Digital Process Monitoring

IoT-enabled sensors and data dashboards track mold performance, temperature stability, and production metrics in real time—supporting supply visibility.

2. Sustainable Material Use

Biopolymer and recycled resin options support green initiatives without compromising GMP compliance.

3. Multi‑component and Insert Molding

Techniques like insert molding support embedded sensors, RFID tags, or dual‑material components within a single production cycle.

4. Short-line Change Flexibility

Quick mold swaps and SOP-standardized practices enable lean production for seasonal or limited-use therapeutic products.

Application Areas & Use Cases:

| Product Type | Key Benefits of Injection Molding |

| Auto‑injectors & pens | Ergonomically precise components with assembly consistency |

| Prefilled syringes | Sterile consumables with integrity-tested closures |

| Vials, caps, and closures | High-volume standard parts with material traceability |

| Tray inserts & test holders | Clean‑room compatible secondary packaging |

This approach ensures that each product component delivers quality as reliably as the formulation within.

Future Outlook & Market Opportunities:

Injection molding in pharmaceutical contract manufacturing is growing significantly—driven by rising demand for injectable biologics, combination devices, and patient-centric delivery forms. As brands seek integrated partners capable of supporting complex device formats, CDMO pharma providers with molding expertise will be in high demand.

India’s strength in cost-effective manufacturing and regulatory compliance positions firms like Windlas Biotech to lead this evolution—serving global markets with scale, consistency, and capability.

Final Thoughts:

Injection molding machines are more than factory assets—they are strategic enablers for modern pharma scale-up. They deliver speed, precision, and repeatable quality at volumes necessary for today’s therapeutic innovation.

With Windlas Biotech’s integrated manufacturing, formulation, and molding ecosystem, pharmaceutical partners can expand capacity confidently—knowing each component is designed, molded, and validated in support of health outcomes, global compliance, and patient safety.